Thermoplastic composite compression molding technology is an advanced manufacturing technique that combines the advantages of thermoplastic materials and composites. Through the compression molding process, it achieves high-performance, high-precision, and high-efficiency product manufacturing. This article aims to introduce the principles, characteristics, applications, and future trends of thermoplastic composite compression molding technology, providing a reference for research and applications in this field.

I. Principles of Thermoplastic Composite Compression Molding Technology

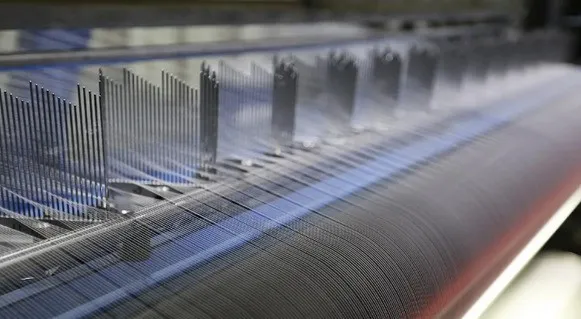

Thermoplastic composite compression molding technology involves the molding of thermoplastic resins with reinforcing materials (such as glass fibers, carbon fibers, etc.) under high temperature and pressure conditions. During the molding process, the thermoplastic resin forms a three-dimensional network structure under the action of the reinforcing materials, resulting in reinforcement and toughening of the material. This process features high molding temperatures, high molding pressures, and short molding times, enabling the production of complex structures and high-performance products.

II. Characteristics of Thermoplastic Composite Compression Molding Technology

1. High Performance

Thermoplastic composite compression molding technology can produce high-performance products with excellent mechanical, thermal, and chemical properties.

2. High Precision

This process enables the manufacturing of products with high precision and complexity, satisfying various applications requiring stringent accuracy.

3. High Efficiency

Thermoplastic composite compression molding technology boasts a short molding cycle and high production efficiency, suitable for large-scale production.

4. Environmental Friendliness

Thermoplastic composites are recyclable, meeting the requirements of sustainable development and possessing good environmental properties.

III. Applications of Thermoplastic Composite Compression Molding Technology

This technology finds extensive applications in aerospace, automotive, rail transportation, electronic information, sports equipment, and other fields. For instance, in the aerospace industry, thermoplastic composites are used to manufacture high-performance products such as aircraft and satellites. In the automotive sector, they are employed in the production of lightweight and high-strength automotive components. And in rail transportation, they are utilized in the fabrication of structural parts for high-speed trains and subways.

IV. Future Trends of Thermoplastic Composite Compression Molding Technology

With continuous technological advancements and expanding applications, thermoplastic composite compression molding technology will encounter more opportunities and challenges in the future. Here are some predicted trends:

1. Material Innovation

Developing novel thermoplastic resins and reinforcing materials to enhance the composite’s comprehensive performance and meet more demanding applications.

2. Process Optimization

Further improving and optimizing the thermoplastic composite compression molding process to increase production efficiency, reduce energy consumption, and minimize waste generation, thereby achieving green manufacturing.

3. Intelligent Development

Integrating intelligent technology into the thermoplastic composite compression molding process to automate, digitize, and intelligentize the production process, improving both efficiency and product quality.

4. Expanding Applications

Broadening the application of thermoplastic composite compression molding technology, particularly in emerging industries such as new energy, environmental protection, and biomedical, to promote industrial upgrading and development.

In conclusion, thermoplastic composite compression molding technology, as an advanced manufacturing technique, possesses vast application prospects and tremendous development potential. With continuous technological innovation and expanding applications, it will play a significant role in more fields, making greater contributions to the development of human society.