Van or Truck Bodies

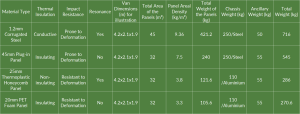

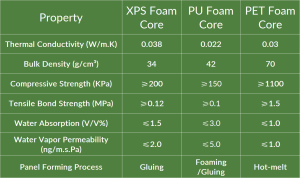

Accentuate your van or truck’s thermal efficiency and lightweight design with PET foam sandwich panels. Featuring UV-resistant, reinforced PET skins and high-density foam cores, these panels offer optimal temperature control and substantial weight reduction, ensuring cargo arrives pristine while boosting fuel efficiency.

Importance of Lightweighting

The substitution of lightweight materials demonstrates significant benefits for both traditional gasoline vehicles and electric vehicles.

Traditional Gasoline Vehicles

- When the overall vehicle weight is reduced by 10%, the following improvements can be achieved:

- Fuel efficiency increases by 6% to 8%

- Service life extends by 50%

- Kinetic energy consumption decreases by 10%

- Braking distance shortens by 5%

Electric Vehicles

- For every 10 kilograms of weight reduction, the driving range increases by 2.5 kilometers.

In summary, lightweight materials bring remarkable benefits to vehicles, enhancing fuel efficiency, prolonging service life, minimizing kinetic energy consumption, and expanding driving range. Our PET foam panels are tailor-made for achieving vehicle lightweighting.

Thermal Insulation

When it comes to van or truck bodies requiring thermal insulation, or specifically refrigerated ones, PET foam panels stand out as a top-notch choice. These panels are essential for vehicles transporting perishable foods, fresh beverages, delicate artworks, precision instruments, temperature-sensitive chemicals, and pharmaceuticals. PET foam panels can seamlessly integrate as doors, backs, side panels, or even tops and ceilings, ensuring comprehensive coverage.

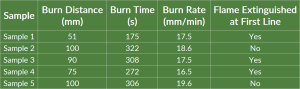

Fire Resistance

• When not treated with flame retardants, PET Foam Panels exhibit a certain degree of flammability, with a flame spread rate of approximately 18mm/min.

• Upon the addition of flame retardants, the combustion rating of PET Foam Panels can be upgraded to V0 level according to the UL94 standard.

Panel Treatments Overview

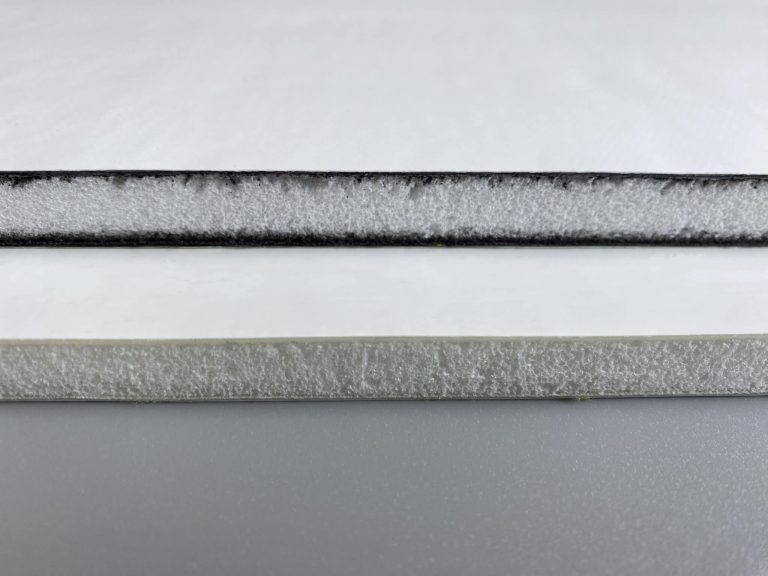

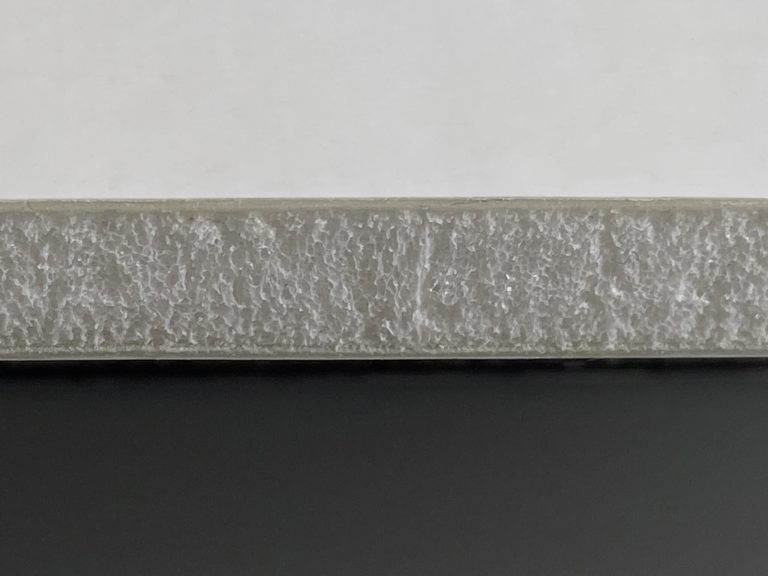

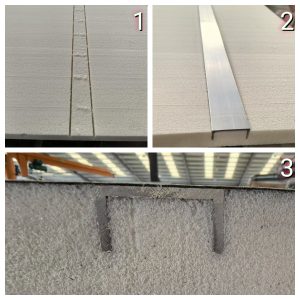

• Special Edge Treatment

Here is a unique edge treatment for our PET foam panels: one surface extends with a deliberately untrimmed border. This design is specially crafted for van truck roofs, where the untrimmed section overlaps seamlessly with the upper wall panel. This approach ensures exceptional waterproofing, highlighting the uniqueness of our PET foam panels’ edge treatment.

• Pre-embedded Reinforcing Ribs or Fixtures

On request, we integrate aluminum alloy profiles or metal reinforcements into PET foam panels, boosting stiffness for specialized uses. High-precision CNC routing pre-cuts grooves for easy assembly. Reinforcements are inserted, then thermally bonded with outer layers, creating a durable sandwich panel. Optionally, metal blocks can be embedded for extra fixation during installations.

• Pre-embed nuts

For PET foam panels needing non-through connections, pre-embedded nuts are perfect. They’re securely embedded using ultrasonic welding, ensuring strong bond. During installation, bolting to these nuts provides a stable, high-strength link to supporting accessories.

Other Features

- PET foam panels feature closed-cell rigid foam, practically impervious to water absorption. This characteristic is particularly advantageous for fresh or frozen aquatic products.

- The combination of lightweight, durability, and longevity ensures these panels will stand the test of time.

- PET foam panels are resilient to impact, corrosion, and mildew, ensuring reliable performance in various environments.

- 100% recyclable, PET foam panels are a green choice for today’s eco-conscious businesses.

We'd love to hear from you!

Don’t miss out on this opportunity to upgrade your van or truck bodies with our top-notch PET foam panels. Contact us today for more information or read the case.