Trailer Floors

Transforming trailer floors into a modern marvel, PP honeycomb floors offer the perfect upgrade for lightweight trailers. Featuring unmatched lightweight durability, anti-skid properties, weatherproofing, and effortless upkeep, they’re ideal for luggage trailers, light cargo trailers, and more.

Trailer Floors Overview

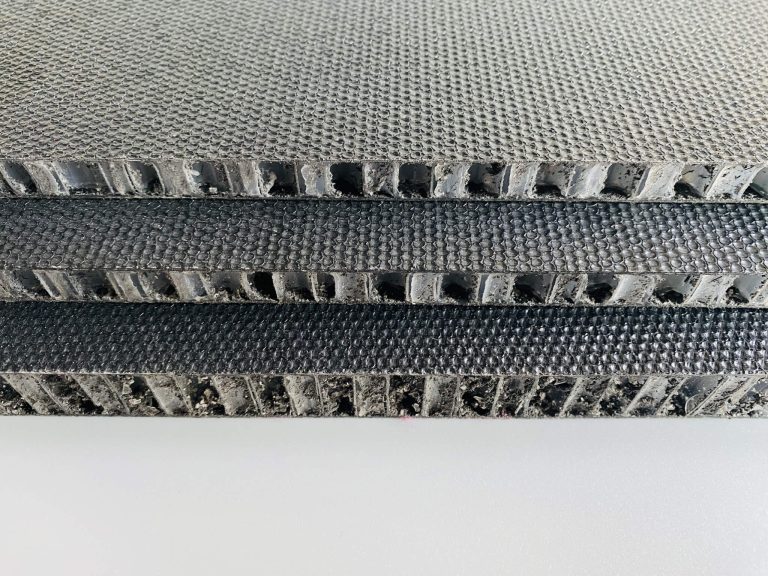

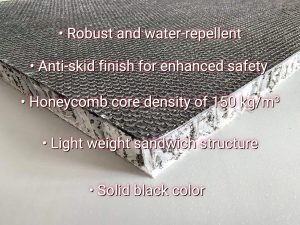

Our PP Honeycomb Panels, specifically tailored for trailer floors, provide a robust and water-repellent solution. Unlike wooden floors that are prone to warping, swelling, or decaying upon moisture exposure, our composite floor is engineered to withstand water damage, guaranteeing long-lasting and dependable performance. This makes them the perfect option for trailers subjected to diverse weather conditions and potential water spills.

Our trailer floors typically feature a honeycomb core with a density of 150 kg/m³, encapsulated by continuous glass fiber-reinforced PP sheets on both the top and bottom surfaces. These floors are predominantly manufactured in a solid black color and come with an anti-skid finish for enhanced safety. Crafted from glass fibers and thermoplastic materials, they offer the advantage of being 100% recyclable.

Trailer Floors Specifications

• Thickness

The most common trailer floor thicknesses are 12mm, 15mm, and 18mm, but we can customize any thickness with a +/-0.5mm precision to meet client needs.

• Length

We can produce composite floors of any length by manufacturing them continuously and then trimming to size.

• Width

Our manufacturing equipment allows us to produce composite floors with a maximum width of 2600mm.

• Density

Our composite floors boast a lightweight design. For instance, a 15mm thick floor has an areal density of just 4.97 kg/m², making it 54% lighter than marine plywood of the same thickness.

| Thickness | Common sizes include 12mm, 15mm, and 18mm. All thicknesses can be customized.

Tolerance: +/-0.5mm |

| Length | Theoretically, floors of any length are available. |

| Width | Up to 2600mm. |

| 12mm | 4.52 kg/m² (Composite) | 8.58 kg/m² (Marine Plywood) | 47% (Weight Saved) |

| 15mm | 4.97 kg/m² (Composite) | 10.73 kg/m² (Marine Plywood) | 54% (Weight Saved) |

| 18mm | 5.42 kg/m² (Composite) | 12.87 kg/m² (Marine Plywood) | 58% (Weight Saved) |

Excellent Loading Capacity

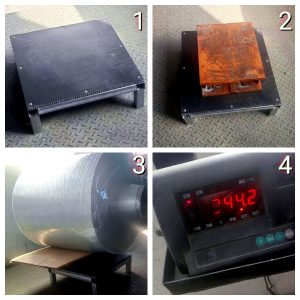

The Composite Trailer Floors, featuring a hot-melt production process, a unique sandwich structure, and a continuous fiber-reinforced surface layer, exhibit exceptional bending and compressive strengths. To visually demonstrate the floor’s load-bearing capacity in practical applications, we conducted a rigorous test.

We designed a specialized setup where a composite floor, approximately 16mm thick, was securely attached to a square profile, covering an area of 2.726 square feet. During the test, the floor was subjected to a substantial weight of 344.2 kg. Impressively, the floor remained fully intact, without any visible signs of stress or deformation. This experimental setup clearly underscored the material’s capacity to support significant loads while maintaining its structural integrity.

We'd love to hear from you!

For lightweight trailers designed to carry luggage, our composite floors are an outstanding option. They offer robustness, stability, and are both lightweight and cost-effective. Furthermore, they are eco-friendly, featuring water/rain resistance and anti-skid surfaces for safer use in snowy conditions. Resistant to corrosion, mildew, and chemicals, they guarantee long-lasting performance.

Ready to make a decision? Contact us to discover how our composite trailer floors can improve your trailers.