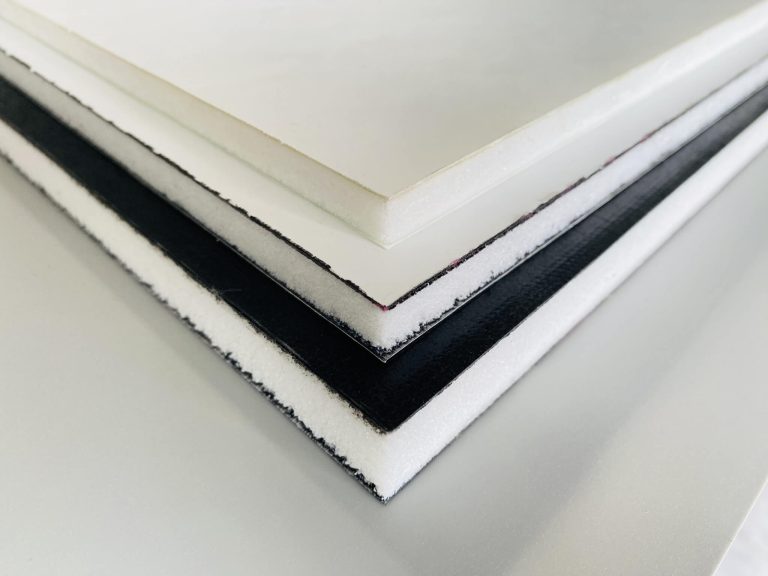

RV Roof or Side Panels

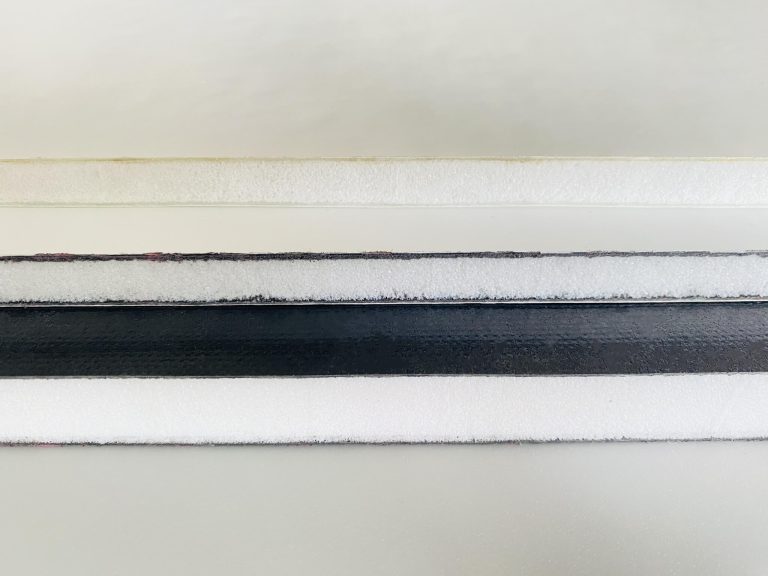

CFRT PET Foam Panels for RV Roof or Side Applications: Lightweight Thermoplastic Foam Sandwich Boards featuring a PET Core. Reinforced with continuous glass fiber-reinforced PET resin UD tape in a 0°/90° orientation, fused via hot-melt process for robust construction. Versatile surface integrates seamlessly with PET films or decorative composites, ideal for enhancing both aesthetics and functionality of RV roofs or side panels.

RV Panels Overview

The materials for recreational vehicles (RVs) must meet strict criteria for performance, safety, durability, and comfort.

- They must be lightweight, waterproof, flame-retardant, and durable.

- They should be eco-friendly and contain minimal harmful substances to protect health.

- They also need to be strong and stable to support the RV’s structure and weight.

- Panel’s thermal insulation is crucial for maintaining a comfortable interior temperature.

Our PET foam panels fulfill all these requirements and are ideal for RV production.

Lightweight, Waterproof, Flame-retardant & Durable

• Lightweight

PET foam panels are lightweight panels, and when considering a 25mm thickness for use in RV wall panels, they weigh approximately 5.75kg per square meter. In comparison, marine plywood of the same thickness weighs around 17.88kg per square meter, making PET foam panels only 32% the weight of marine plywood.

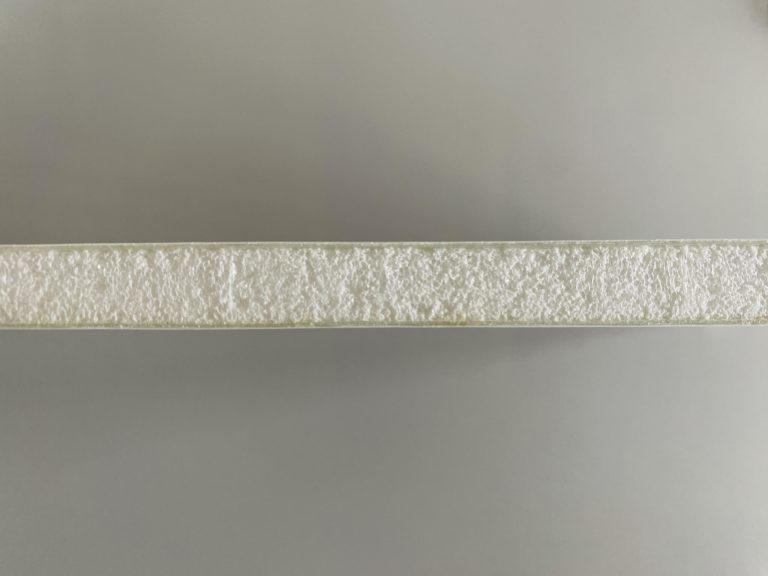

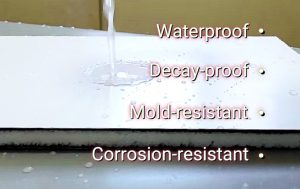

• Waterproof & Durable

Crafted with PET, a high-density, water-resistant polymer, PET Foam Panel exhibits outstanding waterproofness, effectively preventing liquid penetration. Its waterproof, moisture-resistant, and insect-proof properties ensure longevity even in harsh outdoor conditions, while its non-absorbent and non-moldy nature keep your RV interior fresh and durable.

• Flame-retardant

Upon the addition of flame retardants, the combustion rating of PET Foam Panels can be upgraded to V0 level according to the UL94 standard.

Eco-friendly

The materials that constitute PET foam panels include continuous glass fibers, thermoplastic PET resin, and PET foam core. These are combined through a hot-melt process to form a sandwich-style panel, with no addition of adhesives or other substances that may release harmful emissions during production. The PET foam panels produced in this way meet the strict standards of the U.S. FDA for food and drug contact. Furthermore, PET foam panels are 100% recyclable. In summary, PET foam panels are healthy, green, and eco-friendly materials.

Strong and Stable

• A Strong Material

PET foam panels are a type of robust material that boasts exceptional bending and compressive strengths. They also exhibit impressive screw retention capabilities, reaching up to 750N. Taking PET foam panels with densities of 150kg/m³ and 200kg/m³ as examples, their compressive strengths can reach 2.35MPa and 3.34MPa, respectively, while their bending strengths are also highly notable. For detailed figures, please refer to the accompanying table.

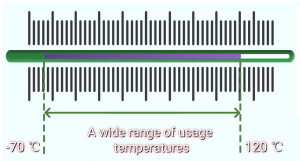

• A Stable Material

PET foam panels are a reliable high-temperature choice for demanding environments, thanks to their durability, heat resistance, and stability. Their ability to retain structural integrity across a working temperature range of -70°C to 120°C makes them ideal for many applications, including as RV panels, where traditional materials may falter.

| 1/2“ | 12.7mm | 150kg/m3 | 103.31MPa |

| 3/4” | 19mm | 150kg/m3 | 79.26MPa |

| 1“ | 25.4mm | 150kg/m3 | 77.48MPa |

| 1/2“ | 12.7mm | 200kg/m3 | 141.18MPa |

| 3/4” | 19mm | 200kg/m3 | 108.69MPa |

| 1“ | 25.4mm | 200kg/m3 | 94.08MPa |

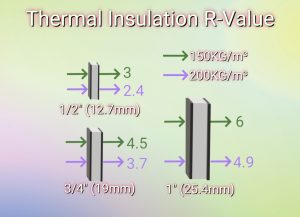

Thermal Insulation

PET foam panels utilize a closed-cell rigid foam structure, which grants them exceptional thermal insulation properties. Specifically, PET foam panels boast a low thermal conductivity coefficient, resulting in a high R-value for thermal insulation. This characteristic enables PET foam panels to effectively prevent heat transfer between the interior and exterior of RV (Recreational Vehicles), thereby creating a comfortable temperature environment inside the vehicle. For the R-values of foam panels with varying core densities and thicknesses, please refer to the accompanying image description.

Customizable Finish or DIY: Create Your Unique Look

The customizable surface of our PET sandwich panel is designed to provide unparalleled flexibility and creativity. With the ability to integrate a diverse array of colors and textures through the use of PET films or decorative composites, you can truly make your RV interior stand out. This versatility not only allows you to showcase your unique personal style but also ensures that your interior retains a sleek, modern aesthetic that is both appealing and timeless.

Moreover, if you have a passion for DIY and want to take an active role in finalizing the finish of your RV interior, we can supply the PET foam panels with nonwoven fabrics attached. Upon receiving the panels, you can simply apply any decorative film of your choice, effortlessly achieving the desired look that perfectly matches your vision and personality.

RV Panel Specifications

• Thickness

The most common RV Panel thicknesses are 1/2″ (12.7mm), 3/4″(19mm), 1″(25.4mm), 2″(50.8mm), but we can customize any thickness with a +/-0.5mm precision to meet client needs.

• Length & Width

By continuously manufacturing and subsequently trimming to the desired dimensions, we are able to produce RV panels of any length, and our manufacturing equipment has the capability to produce panels with a maximum width reaching up to 2600mm.

• Core Density

When PET foam panels are utilized for various applications such as flooring, wall panels, door panels, and roof panels, different core densities are often selected within a range of 80kg/m³ to 250kg/m³ to meet strength requirements while minimizing the weight of the panels to the greatest extent possible.

| Thickness | Common sizes include 1/2″ (12.7mm), 3/4″(19mm), 1″(25.4mm), 2″(50.8mm).

All thicknesses can be customized. Tolerance: +/-0.5mm |

| Length | Theoretically, panels of any length are available. |

| Width | Up to 2600mm. |

| 80kg/m³, 100kg/m³, 150kg/m³, 200kg/m³, 250kg/m³ |

Explanation:

1. For panels that need to support loads perpendicular to their surface, such as floors and roofs– where floors must bear the weight of various RV interiors, occupants, and objects, while roofs must support equipment and snow accumulation in winter – higher density core materials are typically required to enhance their compressive and bending strengths. 2. Conversely, for door panels and wall panels, which do not require significant vertical load-bearing capacity, lower density core materials can be selected. |

We'd love to hear from you!

Embrace the future of RV construction with our cutting-edge PET sandwich panel. Experience the perfect blend of performance, durability, and sustainability that elevates your RV lifestyle to new heights. Feel free to contact us today!