Glass Fiber PP Tapes

Glass Fiber PP Tapes: The Ultimate Reinforcement Solution for Your Industrial Needs

In today’s fast-paced industrial world, having a reliable and versatile reinforcement material is crucial. Glass Fiber PP Tapes are your answer, providing unparalleled strength, durability, and functionality for your various structural applications.

It's a Type of CFRTP

• Thermoplastic

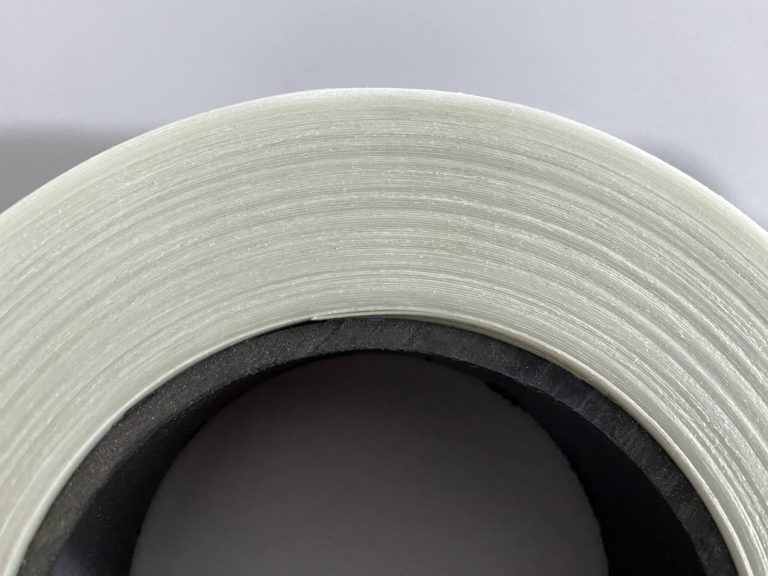

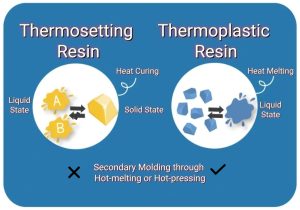

The Glass Fiber PP Tapes we’re discussing are a unique type of continuous glass fiber-reinforced thermoplastic polypropylene tape, belonging to the category of thermoplastic composites. To understand what sets them apart, let’s focus on two key terms: “continuous” and “thermoplastic.” These characteristics distinguish them from traditional FTP or GFRP (glass fiber reinforced plastic). For clarity, we refer to continuous glass fiber-reinforced thermoplastic plastics as CFRTP.

• Flexible for Secondary Processing

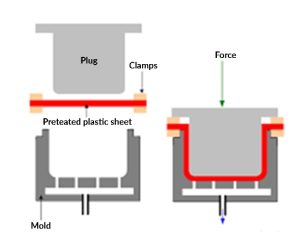

While FTP or GFRP often utilize chopped glass fibers, mats, fabrics, or even continuous fibers embedded in thermosetting resin, which can only be cured once and lacks the flexibility for secondary processing, CFRTP stands out. As a thermoplastic, CFRTP can undergo secondary molding through hot-melting and hot-pressing, allowing for the creation of complex structures as needed.

Green and Healthier

• Free from Harmful Emissions

Furthermore, the production process of CFRTP incorporates the use of thermoplastic resins such as polypropylene (PP), polyethylene (PE), nylon, polyester, and reinforcing glass fibers. Importantly, this manufacturing method eschews the inclusion of any toxic additives, thereby guaranteeing that the resultant products are devoid of detrimental emissions, including formaldehyde. This commitment to safety ensures that consumers can use CFRTP products with peace of mind, knowing they are not exposing themselves or their loved ones to potential health risks.

• 100% Recyclable & Low Carbon Footprint

Moreover, the thermoplastic nature of CFRTP grants it an additional advantage: it is fully recyclable, resulting in a low carbon footprint. This 100% recyclability sets CFRTP apart as an environmentally conscious and sustainable material choice. In today’s world, where the importance of recycling, reducing environmental impact, and achieving a low carbon footprint cannot be overstated, CFRTP stands as a testament to the potential for innovation and sustainability to coexist harmoniously.

Versatile Reinforcing Material for Multiple Applications

In the form of thin tapes, Glass Fiber PP Tapes primarily serve as reinforcing materials. They significantly bolster the structural strength of various applications. For example, when applied to sandwich-structured panels, they greatly enhance the panels’ durability. Alternatively, these tapes can be embedded within wooden beams or plastic boards as reinforcing ribs, improving their overall performance. In skateboards and paddleboards, they augment structural integrity when used in the middle layers. Furthermore, they can be laminated to create sheets of varying thicknesses, suitable for vehicle floors, side wall crash panels, and underbody skirts. They can also serve as the outer layer of foam boards. By laminating them into thicker plates, they can be used in hot-press molding to produce intricate mechanical components.

Specifications & Properties

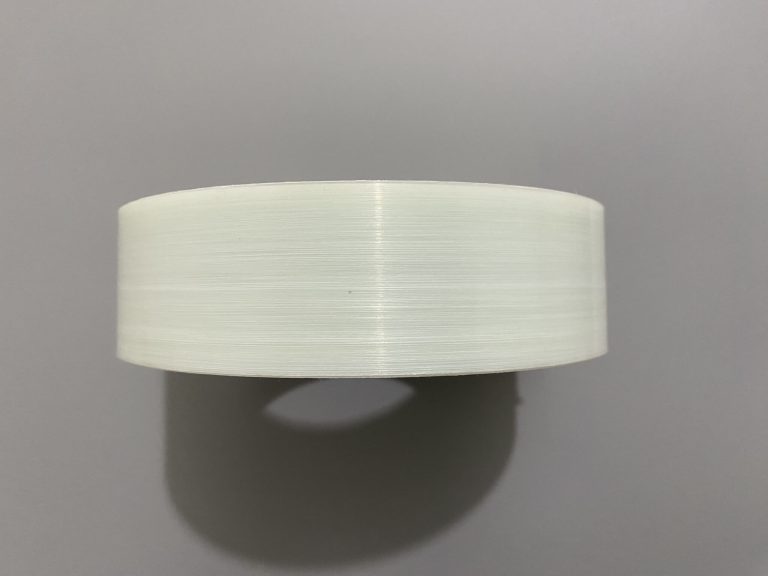

Using our custom molds, we can produce Glass Fiber HDPE unidirectional tapes from 0.18mm to 0.50mm thick. For thicker tapes, we laminate multiple layers. The optimal thickness is 0.3mm, with a tolerance of +/- 0.02mm.

By adjusting the glass fiber content and selecting various grades of raw materials, we manufacture Glass Fiber HDPE unidirectional tapes with different strengths to cater to the diverse needs of our clients.

Beyond strength, these tapes also exhibit excellent electrical insulation, corrosion resistance, high-temperature tolerance, and flame retardancy.

| THICKNESS | 0.18mm – 0.50mm as per requirements |

| WIDTH | 20mm -600mm as per requirements |

| LENGTH | ≤ 4000 meters per roll |

| FIBER WEIGHT CONTENT | 40% – 65% |

| TENSILE STRENGTH | 600 – 1000 MPa |

| TENSILE MODULUS | 28 – 30 GPa |

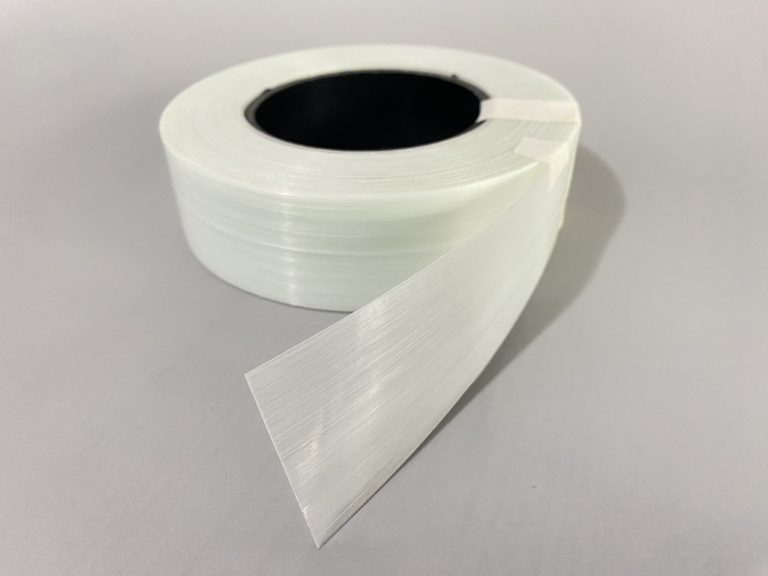

Packaging of Glass Fiber PP Tapes

Glass fiber PE tapes are typically packaged in rolls with either cardboard or plastic cores for protection and ease of use during transportation. Each roll is labeled for traceability and laid flat on either plastic or wooden pallets based on customer preference. To prevent damage and ensure stability, cardboard separators are placed between rolls, and the entire package is wrapped in plastic film. Additionally, a cover is secured on top, and often, an extra layer of plastic film or a cardboard box is added for further protection. The packaging includes side boards to prevent forklift damage. For LCL shipments, we add this protection. For FCL, careful handling reduces damage risk, allowing cost savings by omitting extra protection. For more detailed information, please refer to the packaging instructions for our Glass Fiber PE Tapes product.

We also offer customized packaging solutions tailored to specific customer needs upon request.

We are Happy to Hear from You!

With their unparalleled properties and versatility, Glass Fiber PP Tapes are the perfect choice for your industrial reinforcement needs. Whether you’re looking for a lightweight yet robust material for your brackets or a flame-retardant solution for your support structures, these tapes deliver exceptional performance and reliability.

Glass Fiber PP Tapes are a top-notch reinforcement material, providing superior strength, durability, and functionality for your industrial applications. Don’t hesitate to choose them for your next project and experience the difference.