Glass Fiber HDPE Tapes for HDPE Pipe Winding

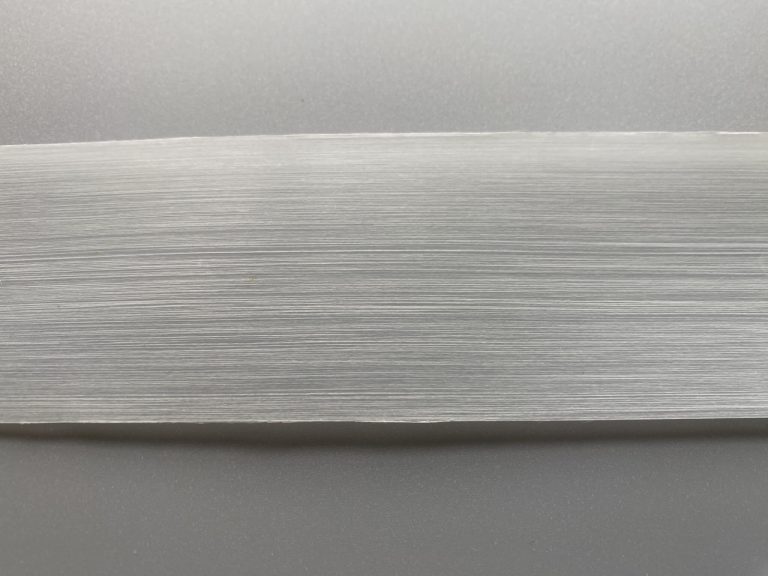

These glass fiber HDPE tapes, precision-engineered for flexibility in pipeline systems, are a revolutionary material in the pipeline industry. They seamlessly marry the uncompromising strength of glass fiber reinforcement with the pliability of HDPE (high density polyethylene), resulting in a composite that is not only robust but also seamlessly integrates with pipe layers.

Product Specifications

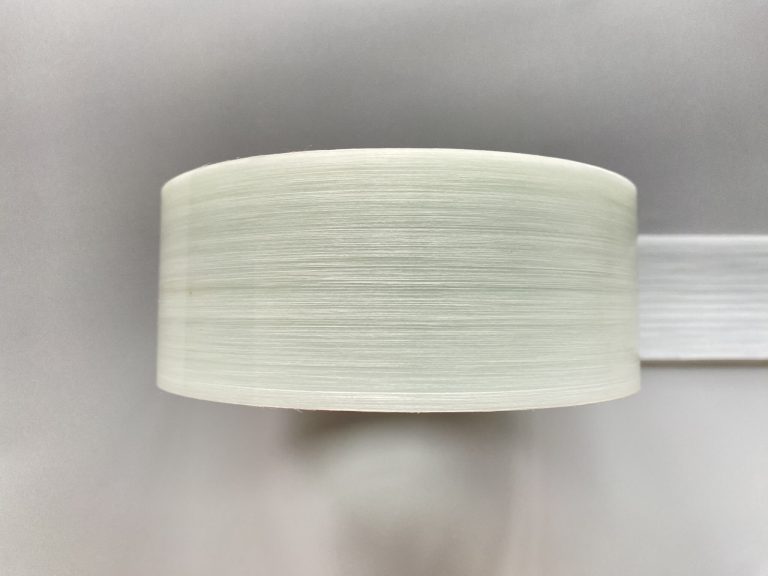

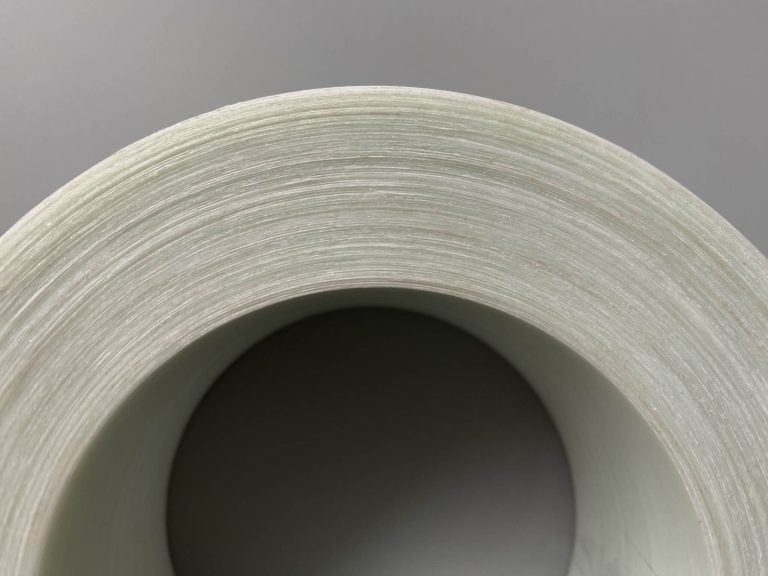

Using our custom molds, we can produce Glass Fiber HDPE unidirectional tapes from 0.2mm to 0.45mm thick. For thicker tapes, we laminate multiple layers. The optimal thickness is 0.3mm, with a tolerance of +/- 0.02mm.

| THICKNESS | 0.2mm – 0.45mm as per customers’ particular requirements |

| WIDTH | 50mm -600mm as per customers’ particular requirements |

| LENGTH | ≤ 4000 meters per roll |

Physical and Mechanical Properties

By adjusting the glass fiber content and selecting various grades of raw materials, we manufacture Glass Fiber HDPE unidirectional tapes with different strengths to cater to the diverse needs of our clients.

| FIBER WEIGHT CONTENT | 40% – 65% |

| TENSILE STRENGTH | 600 – 1000 MPa |

| TENSILE MODULUS | 28 – 30 GPa |

Method of Winding

Depending on whether heating is applied, there are typically two winding methods.

Hot Melt Winding

- It involves heating equipment to melt the Glass Fiber HDPE Tape and tightly adhere it to the pipe surface.

- Common heating equipment includes electric hot air blowers and infrared heaters.

- The resulting connection has high strength and excellent sealing properties, making it suitable for harsh environments such as high pressure and high temperature.

Cold Winding

- It does not require heating equipment, making the construction process simpler and safer.

- Although the strength of the resulting connection may be slightly inferior to hot melt winding, it has sufficient stability and durability in normal temperature and pressure environments.

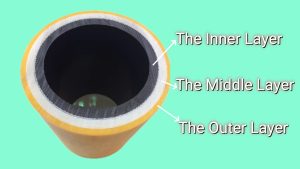

The Reinforcement Middle Layer

Regardless of the winding method employed, glass fiber reinforced HDPE tapes are typically utilized as the middle layer in flexible pipes. These pipes generally consist of three layers: the innermost layer features the best sealing properties to prevent leakage of transported liquids or gases to the outer layers during conveyance; the middle layer primarily provides robust structural support to ensure the safety of the pipe under high-pressure conditions; and the outermost layer, which directly interfaces with the external environment, plays the most significant role in resisting corrosion and damage from external factors.

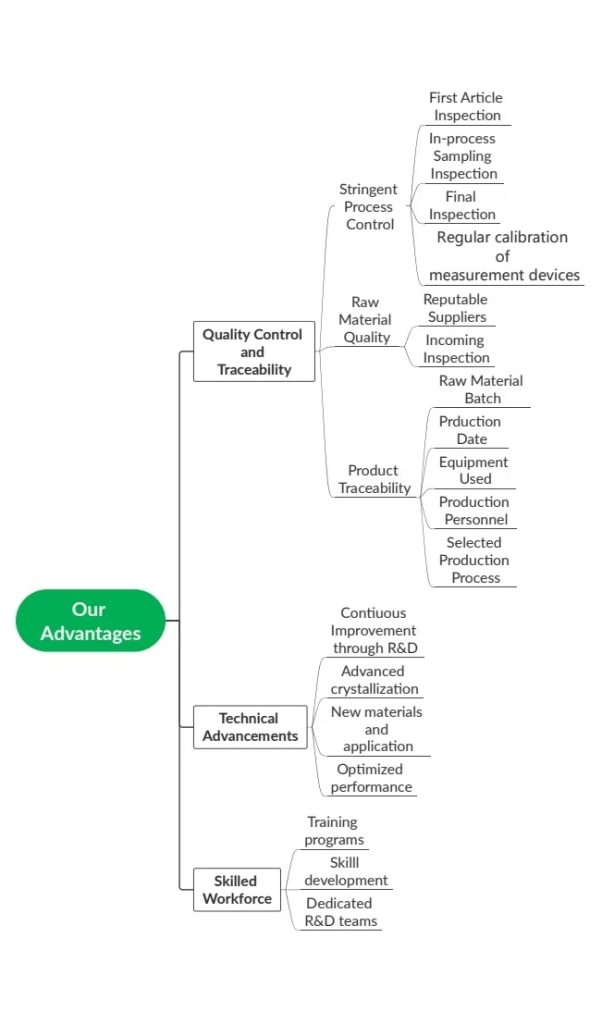

Our Advantages

- Quality Control and Traceability

- Stringent Process Control: During production, rigorous control over dimensions and specs is maintained. Regular calibration of micrometers, calipers, rulers, temperature sensors, and pressure gauges ensures precision and consistency.

- Raw Material Quality: Using high-quality materials from reputable suppliers to ensure superior product quality and performance.

- Product Traceability: By tracing products back to their specific production batch, including details on the resin, fiber, production date, and equipment used, accountability is ensured and quality control is facilitated.

- Technical Advancements

- Continuous improvement through R&D for advanced crystallization, new materials, and applications, coupled with optimized performance featuring enhanced tensile strength and modulus to meet HDPE pipe standards.

- Skilled Workforce

- Offering training programs and skill development to maintain high quality and efficiency in our workforce. Our dedicated R&D teams drive continuous innovation, adapting to evolving market needs.

We are Happy to Hear Your Voice!

Reinforce your pipelines with our revolutionary Glass Fiber HDPE Tapes. Contact us today to start your procurement journey, or read the case.