Glass Fiber PE Tapes

Glass fiber PE tapes, a cutting-edge thermoplastic tape reinforced with unidirectional glass fibers, harness the power of continuous glass fibers and modified polypropylene to create a prepreg tape through a unique process. This advanced tape boasts remarkable mechanical properties, electrical insulation, and sealing capabilities, making it a sought-after solution in industries ranging from automotive and aerospace to water conservancy and oil & gas.

High Specific Strength

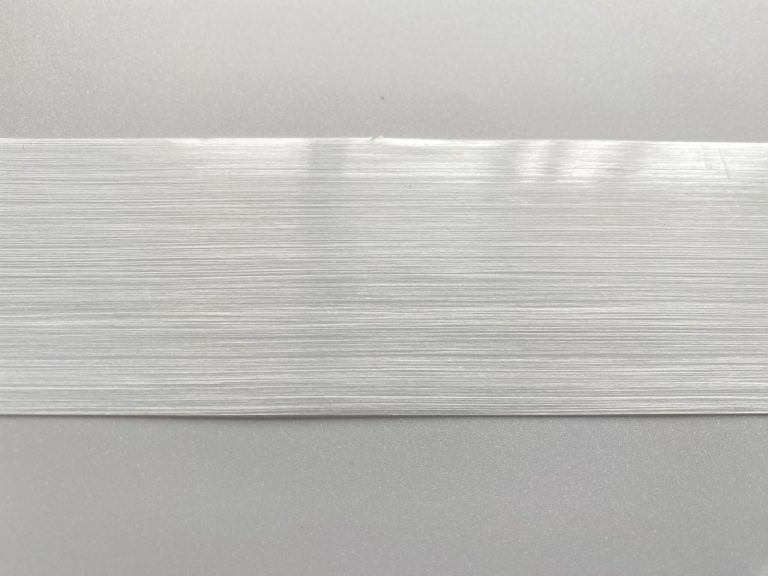

A single-layer PE tape reinforced with glass fiber can be manufactured in thicknesses varying from 0.15mm to 0.5mm. By laminating two or more layers of PE tapes, thicker tapes or even sheets can be produced.

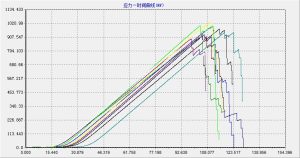

A standard glass fiber reinforced PE tape, measuring 0.3mm in thickness and containing 60% glass fiber, offers an areal weight of around 480g/m². It possesses an average tensile strength of 950 MPa, making it a dependable option for diverse uses.

Q: Are the aforementioned testing results accurate? How is the specimen fixed to the clamp?

We have equipped our universal tensile testing machine with special self-locking clamps, designed specifically to prevent the specimen breakage that is commonly associated with traditional clamping methods. This innovative feature ensures more accurate and reliable testing results by minimizing the risk of unexpected specimen failure during the testing process.

High-Performance Reinforced PE Tape

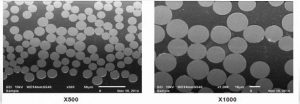

- Material Composition: This tape is crafted from continuous glass fibers thoroughly impregnated in a PE matrix. The glass fibers undergo specialized treatment to ensure they are thoroughly embedded in the PE base.

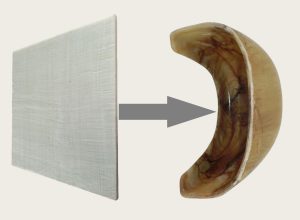

- Thermoplasticity: PE’s thermoplastic nature allows it to be softened and shaped under heat, retaining its new form once cooled. This feature enables the glass fiber-reinforced PE tape to be effortlessly processed and formed using thermoplastic molding techniques.

- Mechanical Properties: Reinforced with continuous glass fibers, this tape exhibits stellar mechanical properties including high strength, exceptional modulus, and outstanding impact resistance.

- Other Properties: Beyond its mechanical prowess, this tape also offers excellent electrical insulation, corrosion resistance, high-temperature tolerance, and fire retardancy.

Various Applications

Glass fiber PE tapes blend glass fiber’s strength and stiffness with PE’s lightweight benefits, ideal for robust, lightweight applications. In automotive, they reinforce parts like bumpers, enhancing safety and fuel efficiency. In aerospace, they bolster aircraft components without significant weight addition, aiding fuel efficiency. In water conservancy, they seal and reinforce structures. And in oil & gas, they act as an enhancement layer for flexible pipes, offering high strength, extended life, and efficient installation for high-pressure use. Across these industries, glass fiber PE tapes excel due to their versatility and performance.

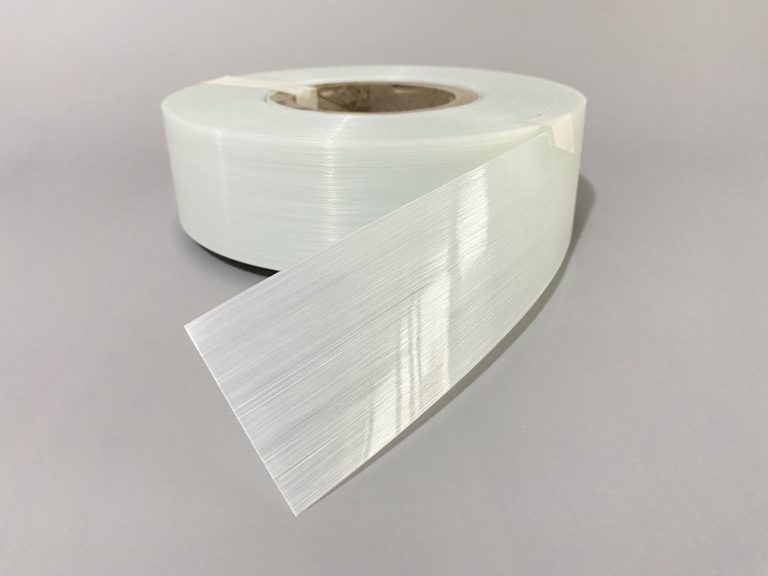

Packaging of Glass Fiber PE Tapes

- Glass fiber PE tapes are typically packaged in rolls with either cardboard or plastic cores at their center. This packaging method ensures that the tape stays intact during transportation and is convenient for customer use.

- Optionally, to further protect the cardboard cores from moisture and deformation during long sea voyages, we can add a plastic plug (please refer to the image, although this is not a mandatory step).

- Each roll is equipped with a small label for traceability, including production date, personnel involved, equipment used, raw material batch number, and more.

- The rolls are laid flat on pallets, which can be made of plastic or wood, depending on customer requirements. In the absence of specific instructions, we will randomly select either wooden or plastic pallets.

- Typically, 5-10 rolls are placed on one pallet, but the exact number depends on the height of each roll and the pallet’s height restrictions, which are often related to the mode of transportation and the height limitations of the customer’s warehouse.

- To prevent friction between rolls, a piece of cardboard is placed between each one. Once the rolls are properly positioned, we wrap the entire package in plastic film to protect it from dust and moisture and to enhance its stability.

- Subsequently, we place a cover on top and secure it with strapping.

- Finally, we usually wrap the entire shipment in an additional layer of plastic film or enclose it in a cardboard box.

While this is our standard packaging method, we will also design a packaging solution tailored to the customer’s specific needs and obtain their final confirmation before implementation.

We are Happy to Hear Your Voice!

To conclude, Glass Fiber PE Tapes represent a superior choice for applications demanding a balance of robustness, lightweight benefits, and versatility. Our tapes harness the strength and stiffness of glass fibers, combined with the lightweight advantages of polyethylene, making them indispensable in various industries. For those interested in exploring the exceptional application of Glass Fiber PE Tapes in flexible pipes within the oil & gas sector, we invite you to take a closer look at our Glass Fiber PE Tapes for HDPE Pipe Winding product. It showcases how our tapes can significantly enhance the performance and reliability of high-pressure flexible pipes, meeting the rigorous demands of this crucial industry.