In the realm of materials science, we are constantly on the hunt for new materials that can lead us into the future. Today, I’d like to introduce you to a remarkable new material that has captured the world’s attention — Continuous Fiber Reinforced Thermoplastic Composite (CFRTP). With its unique properties and vast application potential, CFRTP is gradually transforming our world.

The Enigma of CFRTP

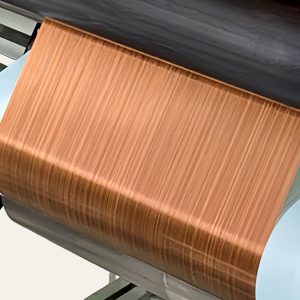

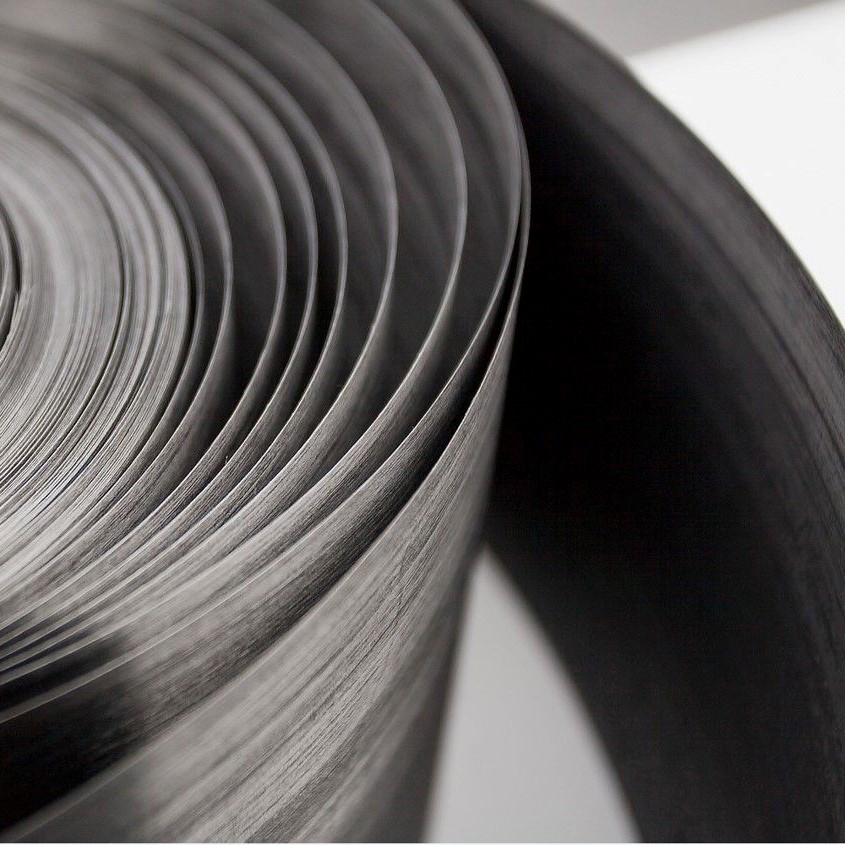

CFRTP, as its name suggests, is a composite material created by seamlessly integrating continuous glass fibers with thermoplastic resin matrix. The continuous glass fibers, renowned for their high strength and modulus, provide a robust framework for the composite. Meanwhile, the thermoplastic resin, with its ease of processing and recyclability, opens up a world of possibilities. The birth of this material marks a significant breakthrough in the field of materials science.

The Unique Advantages of CFRTP

1. Strength and Lightweight

Imagine a car’s body structure that offers sufficient strength to support the body while minimizing weight for improved fuel efficiency. This is where CFRTP shines. Its strength-to-weight ratio enables automakers to design safer and more energy-efficient vehicles.

2. Excellent Thermal Resistance

In the aerospace industry, materials must endure extreme temperatures. CFRTP’s superior thermal resistance makes it an ideal choice for aircraft, rockets, and other aerospace applications. For instance, a specific aircraft’s wing made from CFRTP not only reduces weight but also improves high-temperature resistance.

3. Superior Processability

Unlike traditional thermoset composites, CFRTP boasts enhanced processability. It can be molded through various techniques like injection molding, extrusion, and compression molding. This flexibility and efficiency streamline the manufacturing process.

4. Environmental Friendliness and Recyclability

As environmental awareness grows, recyclable materials are gaining traction. CFRTP, as a recyclable composite, can be melted and reused, minimizing environmental pollution and resource waste.

Application Cases of CFRTP

1. Aerospace

CFRTP has achieved significant success in the aerospace industry. For instance, the wings and fuselage of a particular aircraft are made from CFRTP, enhancing fuel efficiency and performance while reducing weight. Additionally, CFRTP is used in rocket components such as fairings and nose cones, contributing to the successful launch of rockets.

2. Automotive

CFRTP is increasingly finding its way into the automotive industry. A renowned automaker has employed CFRTP in its latest model for body structures and chassis components, achieving lightweight design. This not only improves fuel efficiency but also enhances driving experience and safety.

3. Sports Equipment

CFRTP’s unique advantages are also evident in the sports equipment industry. A renowned golf club manufacturer uses CFRTP for its golf clubs, making them lighter, stronger, and more durable. Furthermore, CFRTP is used in bicycle frames, skis, and other sports equipment, enhancing athletes’ competitive experiences.

Looking Ahead

With continuous technological advancements and cost reductions, CFRTP is poised to showcase its unique advantages in even more sectors. We have reason to believe that in the future of materials science, CFRTP will become an indispensable novel material. Let’s eagerly await its development and applications, and together explore this new world of materials filled with boundless possibilities!