RV Floors

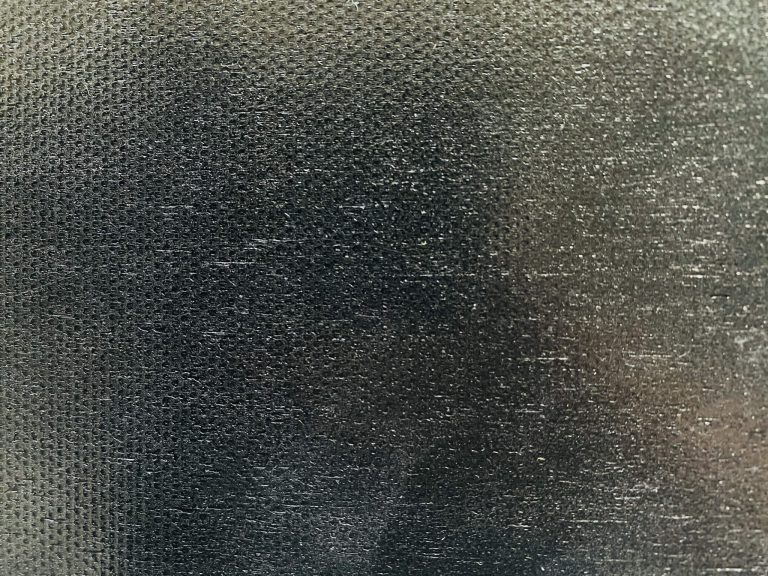

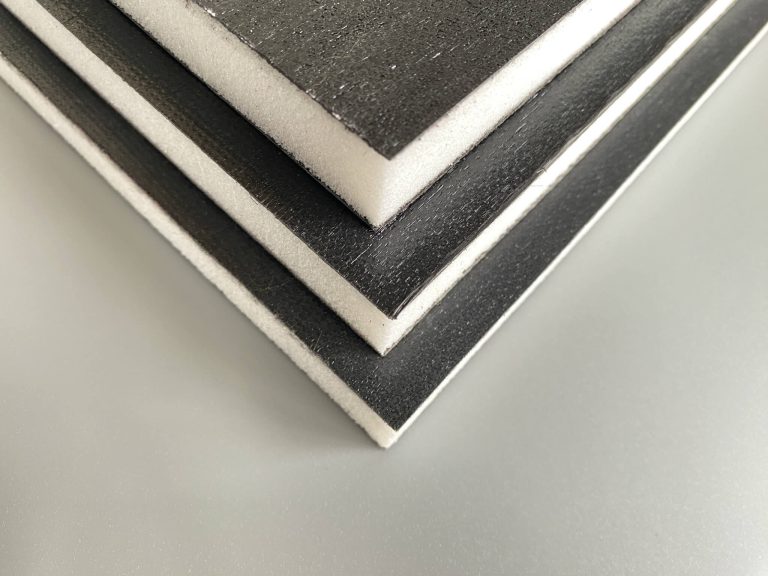

PET foam floors: The ultimate RV solution! Durable, waterproof, thermally insulated, soundproof, and eco-friendly with no harmful emissions. Popular thicknesses: 15mm, 20mm, 32mm. Fiberglass-reinforced with smooth or anti-skid black finish. Explore now!

RV Floors Overview

While both our composite floor offerings, PP Honeycomb panels and PET foam panels, serve as viable options for floors, we advocate for the use of PET foam panels in the RV sector, as they boast several advantages over PP Honeycomb panels within this context. Firstly, PET foam panels provide superior thermal insulation compared to honeycomb cores, significantly minimizing heat transfer from the floor to the exterior, thereby maintaining a comfortable interior climate. Secondly, they exhibit exceptional sound insulation capabilities, drastically reducing road noise, tire noise, and other external sounds from penetrating the cabin during travel, ensuring a tranquil interior atmosphere.

Superior Insulation

• Superior Thermal Insulation

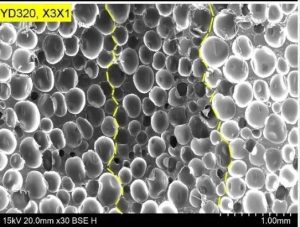

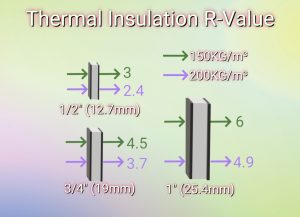

When it comes to RV floors, PET foam panels stand out with their closed-cell rigid foam structure, providing unparalleled thermal insulation. These panels feature a remarkably low thermal conductivity coefficient, translating into a high R-value that efficiently blocks heat transfer between the inside and outside of recreational vehicles. This unique property ensures that PET foam panels, used for RV floors, maintain a pleasant and consistent temperature within the vehicle, enhancing comfort for all occupants.

• Excellent Sound Insulation

When utilized for RV floors, PET foam panels leverage their closed-cell rigid foam structure to offer exceptional sound insulation properties. The foam cores within these panels are specially designed to minimize the transmission of road noise, tire noise, and other external sounds into the cabin during travel. This ensures that the interior of the RV remains serene and peaceful, providing a tranquil environment for occupants.

Connection Methods

When it comes to connecting RV floor panels made of PET foam, there are two primary methods tailored to different needs:

- Rivets or Screws for Through-Type Connections:

- For robust and secure attachment, rivets or screws are often used when the floor panels need to be firmly clamped between metal or other material components on both sides. This method ensures a stable and durable structure, ideal for floors that require high strength and stability.

- Pre-embedded Nuts for Non-Through-Type Connections:

- When a cleaner and less intrusive connection is desired, pre-embedded nuts are the perfect solution. These nuts are securely welded into the floor panels using an ultrasonic welding machine, either before or after production. This preprocessing step guarantees a strong bond between the nut and the floor, allowing for easy and reliable bolt connections during installation. This method maintains the integrity of the floor panel while providing high structural strength.

The choice of connection method for PET foam floor panels in RVs depends on the specific requirements of the floor type and the desired level of stability and aesthetics.

Precision Cutting

We possess high-precision CNC engraving machines capable of accurately cutting panel dimensions, including length and width, with exceptional precision. Furthermore, our machines are versatile enough to carve out various hole structures according to our clients’ specific requirements, fulfilling their unique needs with utmost satisfaction. Whether it’s intricate patterns, specific hole sizes, or complex configurations, our CNC technology ensures that every detail is executed with unparalleled precision and quality.

We'd love to hear from you!

PET foam flooring is the preferred choice for RV manufacturing factories aiming to craft exceptional RV interiors. Its safe and environmentally-friendly production process, outstanding soundproofing capabilities, efficient thermal insulation, durable and comfortable characteristics, as well as high recycling value, make it a standout in the RV manufacturing industry. Contact us today for more information on this product.