Stage Floors

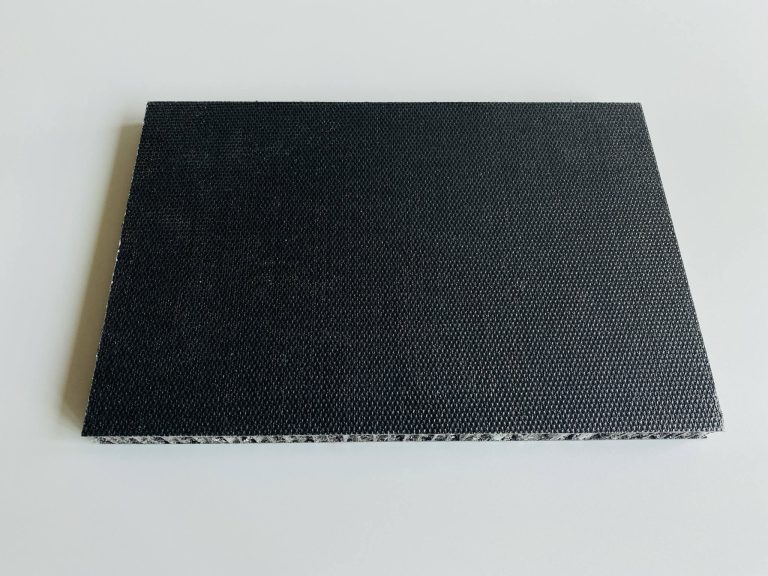

When seeking a dependable and eco-friendly alternative to traditional plywood floors, consider our specially designed sandwich-style stage floors. These floors offer superior durability to support the weight and movements of performers, while also providing elasticity to minimize impact and protect joints.

Stage Floor Overview

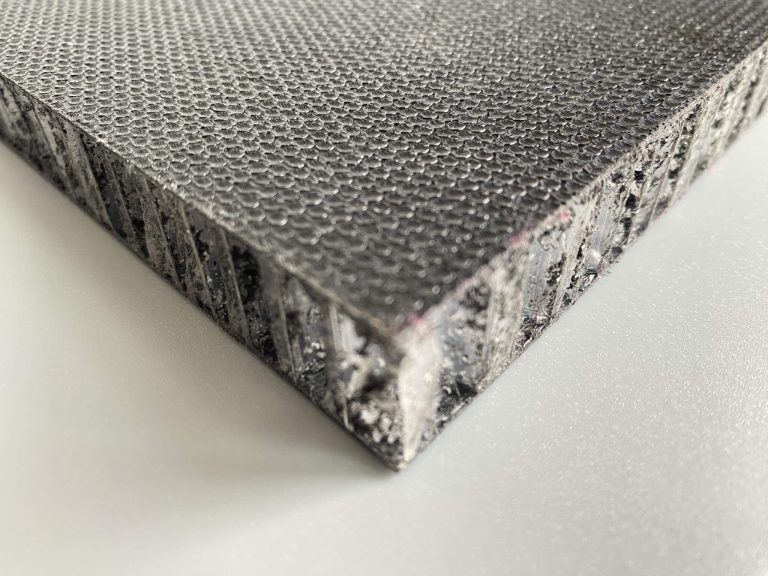

Easy installation, maintenance, and high recyclability make them an environmentally responsible choice. Plus, they’re fire-resistant for enhanced safety. Available in a popular 15mm thickness, these floors feature glass fiber reinforced PP skins and a PP honeycomb core with a 150 KG/m³ density. The anti-skid surface finish in black offers stability and reliability for any performance.

| Material/Structure | PP Honeycomb Sandwich Panels |

| Core Density | 150 KG/m³ |

| Surface Finish | Anti-skid + Black Color |

| Main Thickness | 15mm |

| Main Features | Easy Maintenance/High Recyclability/Fire-resistant |

Safe, Comfortable & Efficient

Composite sandwich panels are the epitome of stage floors, offering unparalleled safety, comfort, and performance for dancers, actors, and all types of performers. Crafted to perfection, these floors are robust enough to withstand the rigorous demands of performers’ weight and dynamic movements, while simultaneously boasting just the right amount of elasticity to cushion impacts and joints. What’s more, installation, maintenance, and even replacements, if needed, are all straightforward and effortless.

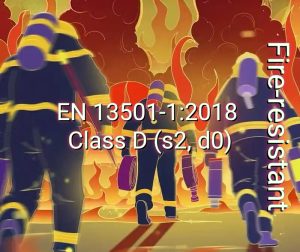

Fire-resistant

PP honeycomb panels are reinforced with glass fiber, which significantly enhances their fire resistance properties. Currently, our manufactured PP honeycomb panels naturally meet the EN 13501-1:2018 standard’s Class D (s2, d0) without the need for additional flame retardants. Furthermore, by incorporating specialized flame retardants, their fire rating can be elevated even further. Stage boards, utilized in densely populated settings, often draw significant attention to their fire rating. Meeting certain fire-resistance standards serves as a valuable advantage and effective support for their use as stage boards.

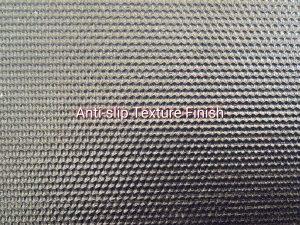

Anti-skid Finish & Edging

• Anti-skid Finish

Composite stage floors feature an anti-skid finish integrated during manufacturing, using hot pressing with a Teflon belt. This process yields a durable, stable surface that significantly minimizes slip and fall risks for performers. Excellent anti-slip properties are vital for ensuring successful, safe performances.

• Edging

For stage boards, we use our proprietary hot-melt edging technology, which is glue-free and highly eco-friendly. This method offers exceptional strength, surpassing traditional hot-melt adhesive edging. However, if the edges are concealed within metal profiles, edging is unnecessary and would only increase costs. In such cases, we advise against it.

We're excited to hear from you!

Discover the unparalleled durability and versatile performance of our stage boards. For inquiries and more information, we eagerly await your contact. Reach out today for a competitive quote!