Composite Floors

Breaking with tradition, Composite Floors have sparked a flooring revolution across industries with their remarkable bending strength, lightweight construction, and enduring durability. Whether for trailers, RVs, event staging, aluminum scaffoldings, or other applications, these multi-layer sandwich floors are the perfect alternative.

Composite Floors Overview

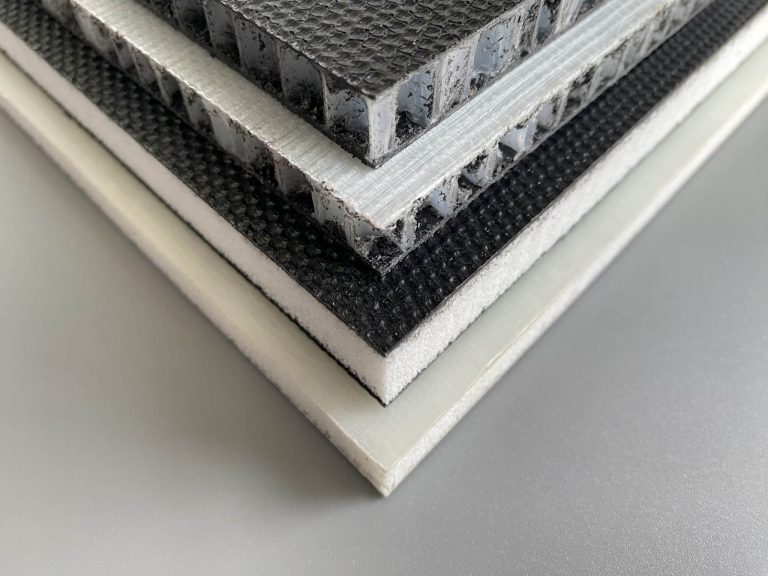

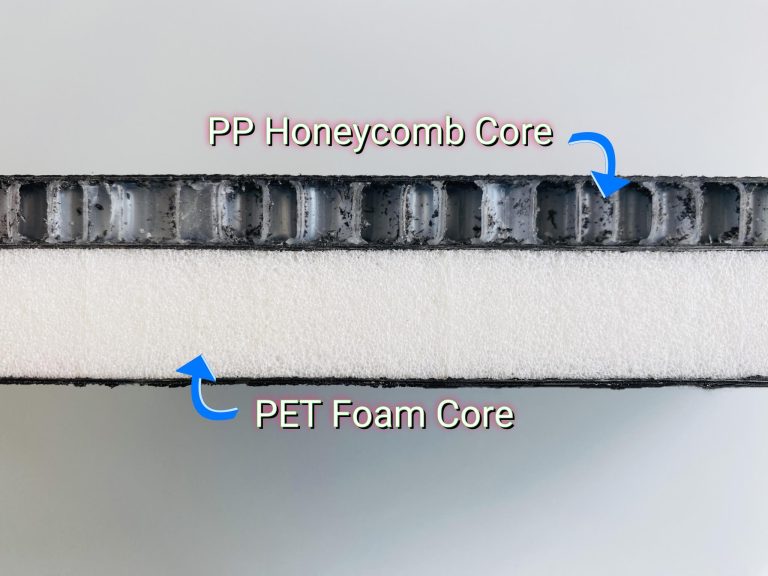

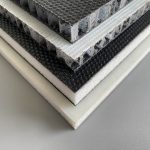

Depending on the application, composite floors can incorporate different core materials—honeycomb or foam. Regardless of the choice, a higher core density is typically utilized. The density of honeycomb cores generally exceeds 150 kg/m³, while foam cores typically have a density of at least 200 kg/m³. For applications without thermal insulation requirements, we recommend using honeycomb cores. However, for sectors demanding thermal insulation, such as recreational vehicles (RVs) and refrigerator trucks’ floors, foam cores are the preferred option. Especially for motorhome floors, foam cores offer several advantages. Firstly, compared to honeycomb cores, foam cores provide superior thermal insulation, effectively reducing heat transfer through the floor to the exterior, thereby maintaining a comfortable interior temperature. Secondly, foam cores exhibit excellent sound insulation properties, minimizing road noise, tire noise, and other external sounds transmitted into the cabin during travel, ensuring a serene interior environment.

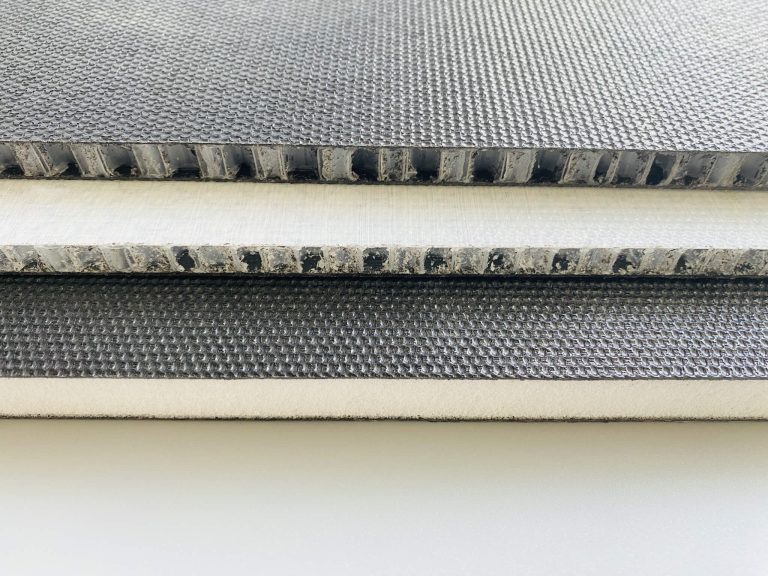

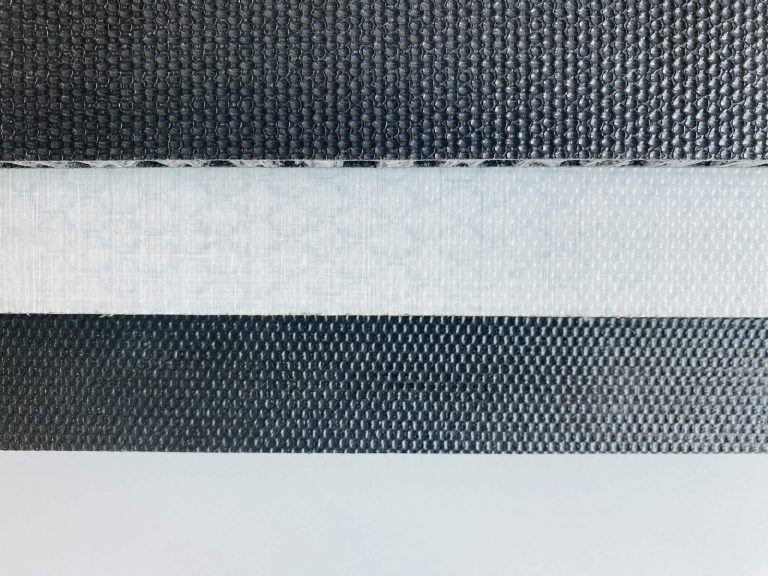

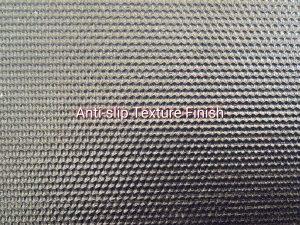

Anti-slip Texture Finish

The surfaces of composite floors are typically treated with an anti-slip texture. Unlike plywood or other similar products where the anti-slip feature may be applied after production, the anti-slip texture on composite floors is formed directly on the surface during the manufacturing process through hot pressing with a Teflon belt. This results in an extremely durable and stable anti-slip surface. By incorporating this anti-slip texture, the product significantly reduces the risk of slips and falls for users engaging in activities such as walking or working on it. Especially when used as stage floors, maintaining good anti-slip properties is crucial for ensuring performers can successfully complete their acts.

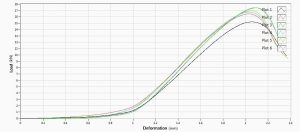

Excellent Compressive Strength

When composite boards are utilized as flooring materials, compressive strength is a vital performance metric. This metric directly correlates to the board’s ability to maintain structural integrity under specific loads, preventing it from collapsing. In this regard, both our honeycomb panels and PET foam panels exhibit exceptional compressive strength.

Taking the 12.5mm thickness as an example, let’s delve into the compressive strength performance of these two flooring materials:

-

Honeycomb Panels: Core Density: 150 kg/m³, Compressive Strength: 4.63 MPa. Thanks to its unique honeycomb structural design, the 12.5mm thick honeycomb panel excels in compressive strength, capable of bearing significant vertical loads without deformation.

-

PET Foam Panels: Core density: 200 kg/m³, Compressive Strength: 3.63 MPa. With the same 12.5mm thickness, PET foam panels also demonstrate satisfactory compressive strength. The optimization of its internal structure enables the panel to remain stable under pressure, resisting deformation.

In summary, both honeycomb panels and PET foam panels excel in the key performance metric of compressive strength, providing a robust guarantee for the selection of flooring materials.

Composite vs. Wooden & Metal

Composite floor, with its chemical stability and lightweight properties, has become a popular choice for various applications, such as trailer floors, stage floors, and scaffolding deck floors, etc. Unlike traditional flooring materials, composite floor eliminates the concerns associated with wood and metal floors in these specific environments.

For trailer floors, composite floor offers a durable and water-resistant solution. Unlike wood floors, which can warp, swell, or rot when exposed to moisture, composite floor is designed to resist water damage, ensuring a long-lasting and reliable performance. This makes it an ideal choice for trailers that are exposed to various weather conditions and potential water spills.

For stage floors, composite floor provides a lightweight and versatile option. Its chemical stability ensures that it will not degrade or deteriorate over time, maintaining a consistent and reliable performance. Additionally, its lightweight nature allows for easier installation and handling, which is crucial for stage setups that require frequent changes and adjustments.

For scaffolding deck floors, composite floor offers a corrosion-resistant and durable solution. Unlike metal floors, which can corrode when exposed to acidic or alkaline substances, composite floor is designed to resist corrosion, ensuring a long-lasting and safe performance. This makes it an ideal choice for scaffolding that is used in various environments, including construction sites and industrial settings.

Overall, composite floor’s combination of chemical stability, lightweight properties, and resistance to water and corrosion makes it an ideal choice for those seeking a durable and reliable flooring option in many industries.

Connection Methods

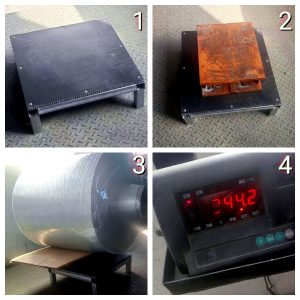

• Rivets or Screws

When the floors adopt a through-type connection method, rivets or screws are typically chosen for fixation. This connection method is characterized by metal or other material components being installed on both sides of the floor, while the floor itself is clamped in the middle, forming a stable structure. By penetrating and securing with rivets or screws, a firm connection between the floor and the supporting components can be ensured.

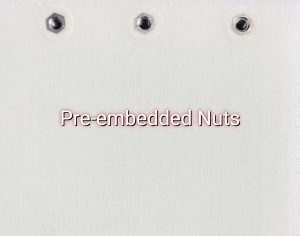

• Pre-embedded Nuts

For floors that require a non-through-type connection, pre-embedded nuts become an ideal choice. The implementation process of this connection method involves embedding nuts into the interior of the floor using an ultrasonic welding machine either after floor production or before installation. This preprocessing ensures a high pull-out strength between the nut and the floor, guaranteeing the reliability of the connection. During subsequent installation, simply connecting the bolt to the pre-embedded nut can easily achieve a stable connection between the floor and the supporting accessories, with high structural strength.

The connection methods for composite floors and their supporting components are diverse, and the choice of method depends on the floor types and the connection requirements.

We're Happy to Hear Your Voice!

In today’s demanding industrial and commercial environments, traditional plywood and metal flooring fall short. But our sandwich-style anti-slip composite floors are the innovative solution you’ve been waiting for.

Unlike conventional materials, our composite floors offer a unique blend of superior strength, lightweight design, and long-lasting durability. Whether it’s high humidity or electrical insulation, our floors excel in every aspect. Choose from PP honeycomb or PET foam construction to suit your specific needs.

Don’t Wait, Inquire Now! Transform your space with our revolutionary anti-slip composite floors. Contact us today to start your procurement journey!