In the quest for enhanced box truck performance and efficiency, the use of PET foam panels has emerged as a revolutionary solution. This innovative material is being increasingly adopted in box truck bodies due to its exceptional properties that cater to the demanding needs of the transportation industry. Visit our Van or Truck Bodies page for details.

Key Factors of PET Foam Panels

1. High Strength

One of the key factors driving the successful utilization of PET foam panels is their high strength. The material possesses exceptional structural robustness, enabling it to withstand the rigors of the road and the heavy loads that box trucks often carry. This ensures the safety and durability of the box truck body, minimizing the risk of damage or breakdown during transit.

2. Lightweight

Another significant advantage of PET foam panels is their lightweight nature. Compared to traditional materials like steel or aluminum, PET foam panels are significantly lighter, allowing for a significant reduction in the overall weight of the box truck body. This not only maximizes cargo capacity, enabling box trucks to carry more goods, but also improves fuel efficiency. Lighter box trucks require less energy to move, resulting in lower fuel consumption and reduced emissions.

3. Thermal Insulation

Furthermore, the superior thermal insulation properties of PET foam panels are another crucial factor in their successful application in box truck bodies. These panels effectively maintain optimal temperatures within the cargo space, protecting valuable cargo from extreme external temperatures. Whether it’s perishable goods that need to be kept cool or sensitive equipment that requires a stable temperature environment, PET foam panels ensure that the cargo remains in pristine condition during transit.

| 80 Kg/m³ | 0.028 W/(m*K) | ||

| 100 Kg/m³ | 0.03 W/(m*K) | ||

| 200 Kg/m³ | 0.038 W/(m*K) |

The combination of these benefits makes PET foam panels an ideal choice for truck bodies. Not only do they enhance the structural integrity and durability of the truck, but they also maximize cargo capacity and improve fuel efficiency. Additionally, their superior thermal insulation properties ensure that cargo remains safe and protected during transportation. As the transportation industry continues to evolve, PET foam panels are poised to play an increasingly important role in shaping the future of truck bodies. Visit our Van or Truck Bodies page for details.

Assembly Illustrations

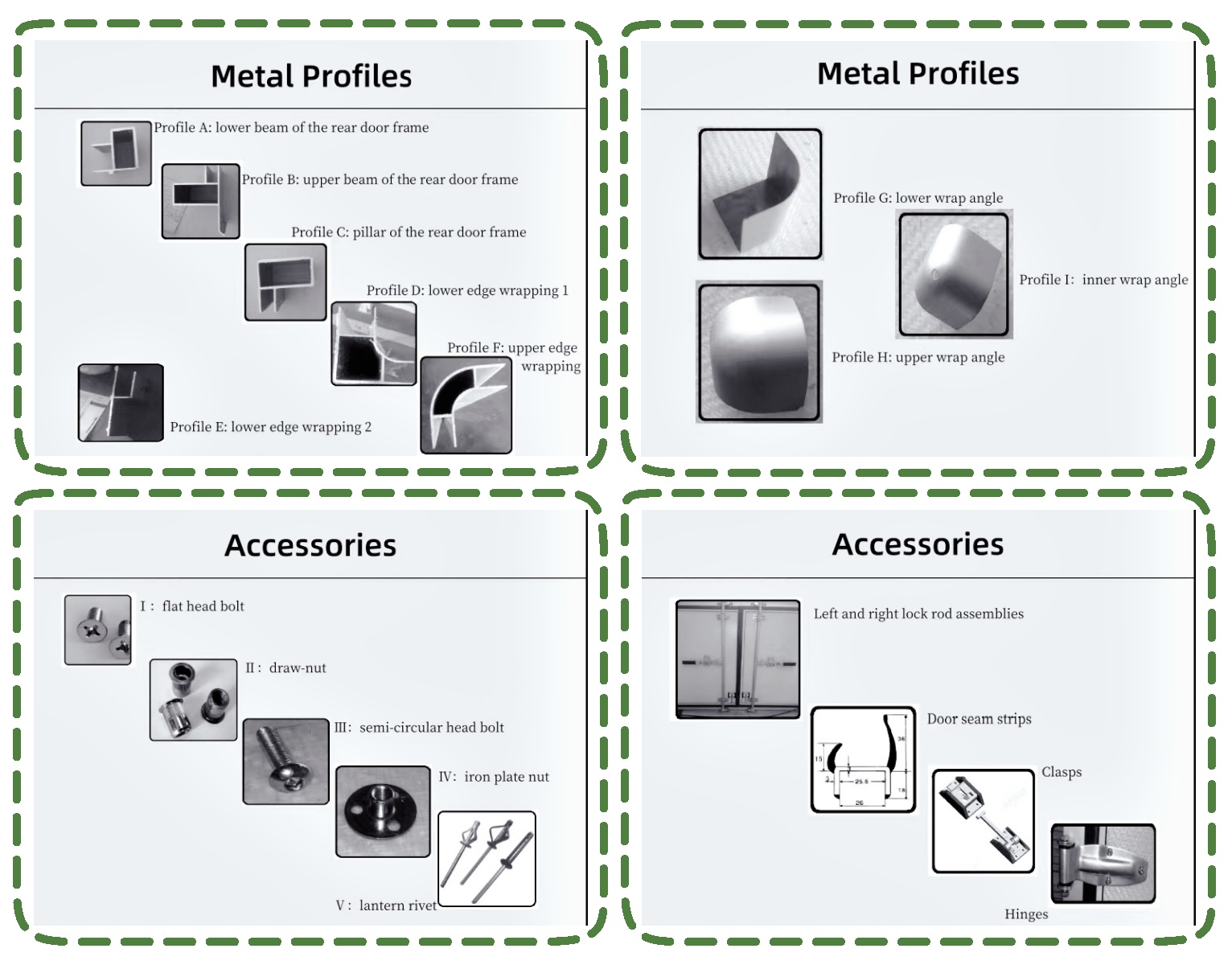

1. Metal Profiles & Accessories Preparation

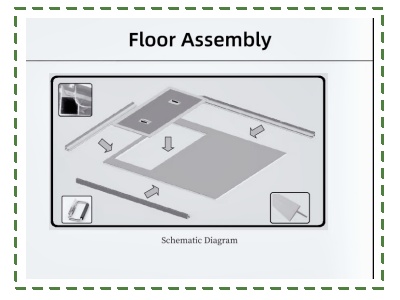

2. Floor Assembly

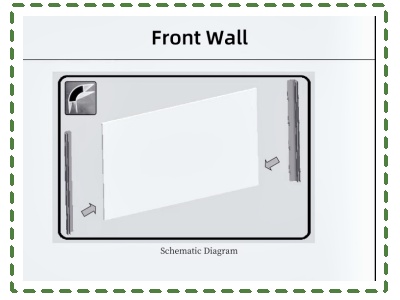

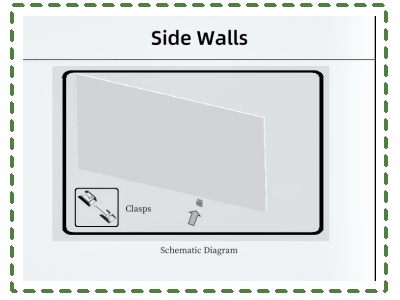

3. Front & Side Walls Assembly

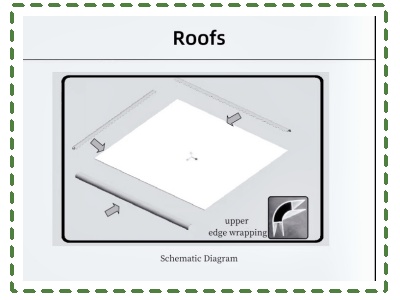

4. Roofs Assembly

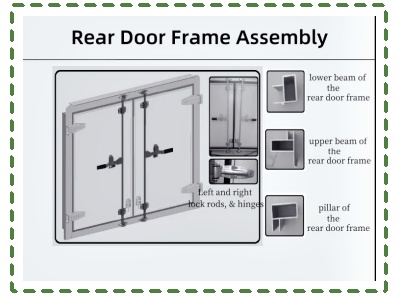

5. Rear Door Frame Assembly

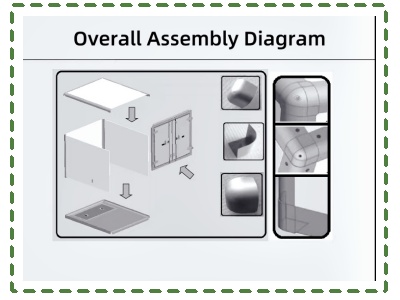

6. Overall Assembly Diagram

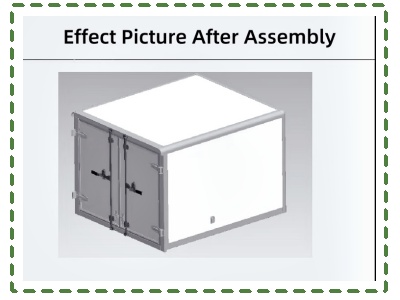

7. Effect Picture After Assembly

Conclusion

PET foam panels utilized in box truck bodies showcase remarkable benefits, especially in weight reduction. By substituting these lightweight materials, both traditional gasoline vehicles and electric vehicles experience significant advantages. For gasoline vehicles, a 10% reduction in overall vehicle weight leads to a 6% to 8% increase in fuel efficiency, a 50% extension in service life, a 10% decrease in kinetic energy consumption, and a 5% shortening of braking distance. For electric vehicles, every 10 kilograms of weight reduction translates to an additional 2.5 kilometers of driving range. Our PET foam panels are tailor-made for vehicle lightweighting, with a box truck (example size: 4.2m x 2.1m x 1.9m) using PET foam panels weighing just 105.6KG, which is a mere 25% of the weight of a truck using 1.2mm Corrugated Steel (421.2KG). Visit our Van or Truck Bodies page for details.