In the wave of global manufacturing pursuing lightweight, efficiency, and sustainability, thermoplastic composites are gradually becoming the core materials in high-end equipment fields. Recently, Pinette PEI, a leading European enterprise in industrial engineering, announced the delivery of the world’s largest thermoplastic stamping press. This pioneering move not only marks a significant breakthrough in thermoplastic composite forming technology but also brings profound implications for key industries such as aerospace and automotive globally.

Technological Breakthrough: Redefining Industry Benchmarks

The thermoplastic stamping press delivered by Pinette PEI is a true “giant” in the industry, boasting a platen size of 5 meters by 2 meters and a pressing force of 30,000 kN (3,000 tons). It is currently the largest and most powerful equipment in the field of thermoplastic composite stamping. Its technical highlights include:

- Ultra-fast Material Transfer: The time from infrared heating to press transfer is less than 5 seconds, significantly enhancing production efficiency.

- Advanced Versatility: Equipped with an automated robotic system, it achieves complete automation in mold release agent handling, sensor coupling, virtual part manipulation, and mold positioning.

- Optimized Energy Management: Through efficient utilization of preheating and cooling stations, as well as uniform heat transfer technology using thermal oil, it reduces energy consumption and improves production sustainability.

These technological innovations have brought the press to new heights in terms of molding precision, production efficiency, and energy utilization, redefining the technological benchmarks for thermoplastic composite stamping.

Strategic Cooperation: Joining Hands with Airbus for a Shared Future

This revolutionary press from Pinette PEI has entered into a strategic cooperation with the global aerospace giant Airbus, integrated into Airbus’ aircraft structural parts factory in Bremen, Germany, and officially put into operation in December 2024. This cooperation aims to accelerate the production of next-generation thermoplastic composite parts and enhance the international competitiveness of the European aerospace industry.

Airbus chose Pinette PEI not only for the press’s outstanding technical performance but also for its deep understanding of thermoplastic composite forming processes. The press supports Airbus in achieving:

- Higher Production Efficiency: Shortening production cycles and increasing productivity through automation and rapid forming technologies.

- Better Cost-Effectiveness: Thermoplastic composites offer a 40% weight reduction, a 10-fold increase in corrosion resistance, and a 35% reduction in manufacturing costs compared to traditional metals.

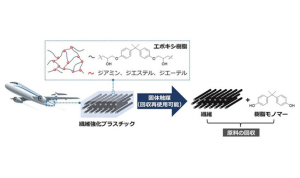

- Enhanced Sustainability: Thermoplastic materials improve recyclability by 80% and reduce carbon emissions by 55%, aligning with the green development trends in the aviation industry.

Industry Impact: Driving Technological Upgrades Across Multiple Fields

- Aerospace Industry: With their high-temperature resistance, impact resistance, and recyclability, thermoplastic composites are becoming ideal materials for key components such as aerospace engines and fuselage structures. Pinette PEI’s press will accelerate this process, assisting manufacturers like Airbus in developing lighter, stronger, and more environmentally friendly aircraft.

- Automotive and Packaging Industries: The forming efficiency and cost advantages of thermoplastic composites are equally attractive to the automotive and packaging sectors. For example, automotive thermoforming technology is driving lightweighting and safety improvements through material innovation and equipment upgrades. The packaging industry utilizes thermoforming machines to efficiently produce containers with complex shapes, meeting consumers’ demands for high-quality packaging.

- Market Competition Landscape: The global thermoforming machine market is currently dominated by leading enterprises, with local manufacturers on the rise. Pinette PEI’s technological breakthrough not only solidifies its leading position in Europe but also prompts global manufacturers to increase investment in technological R&D, driving overall technological upgrades in the industry.

Future Outlook: Endless Technological Innovation

As global demand for sustainable development and high-end equipment grows, the application scenarios for thermoplastic composites will further expand. As an industry pioneer, Pinette PEI will continue to explore:

- Material Innovation: Integrating emerging materials such as bio-based and nanotechnology to enhance composite performance.

- Technological Integration: Deepening the application of automation and digitalization technologies in the production process to achieve higher precision and efficiency.

- Circular Economy: Improving waste recycling systems to promote closed-loop utilization of thermoplastic composites.

Conclusion:

Pinette PEI’s delivery of the world’s largest thermoplastic stamping press is not only a demonstration of the company’s technological strength but also an important milestone in the global manufacturing industry’s advancement towards high-end and green manufacturing. In the future, with the widespread application of thermoplastic composites and continuous technological innovation, we have every reason to expect that this field will bring more groundbreaking solutions to humanity.

Source:Pinette PEI