On December 19th, Hexcel announced a collaboration with Boeing to conduct performance testing on its Flex-Core® HRH-302 honeycomb core material. This product is potentially slated for application in the cladding structure of the engine exhaust nozzles of the U.S. Navy’s MQ-25 unmanned aerial refueling tanker. Visit our products here

The MQ-25, an aircraft carrier-based unmanned aerial refueling tanker introduced by Boeing, is designed to enhance the combat radius of carrier-based fighter jets and electronic warfare aircraft such as the Super Hornet, Growler, and F-35C. Visit our products here

“The use of composite materials not only reduces the aircraft’s weight but also enhances its durability and payload capacity,” said Bobby Rowe, Vice President of Core Materials and Engineered Products at Hexcel. “This allows the aircraft to carry more fuel, sensors, communication equipment, and other mission-critical devices. For aircraft carrier fleets operating across the vast Pacific Ocean, this is crucial.” Visit our products here

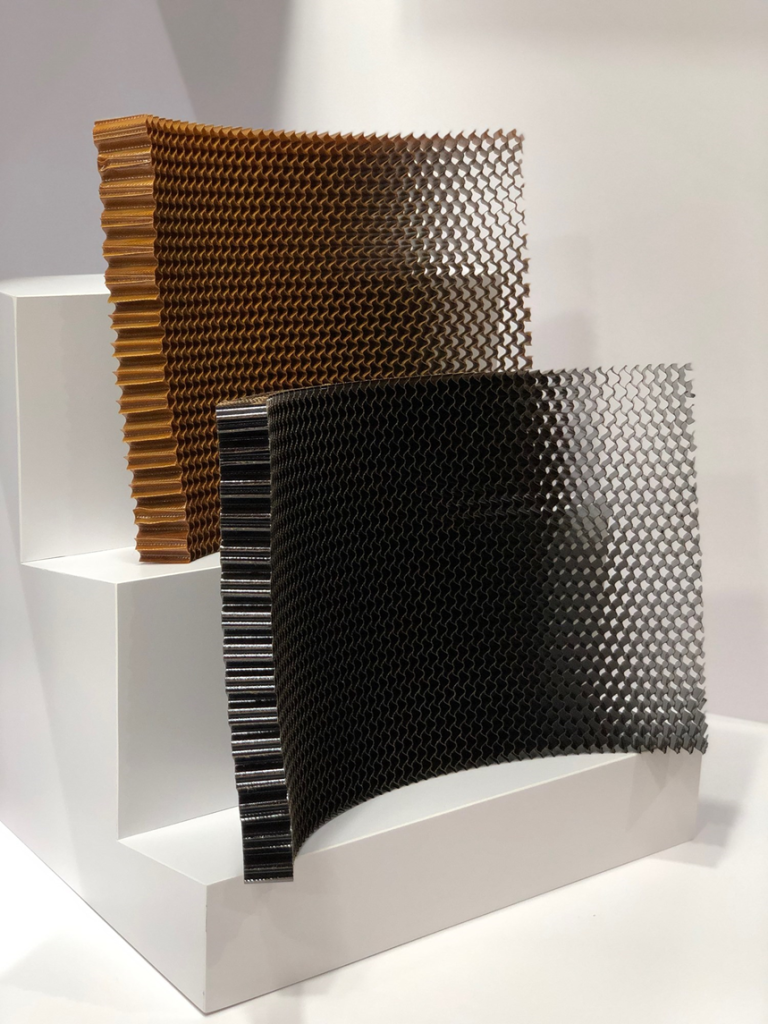

In recent years, Hexcel’s product team has worked closely with Boeing to develop honeycomb core materials that are lightweight, cost-effective, have short production cycles, and meet aircraft performance requirements. Visit our products here

Introduced by Hexcel in early 2024, Flex-Core® HRH-302 honeycomb core material operates at temperatures up to 450°F (approximately 232°C), bridging the gap between traditional phenolic-based materials and higher-cost polyamide-based materials. Leveraging Hexcel’s expertise in thermoplastic resins, this material further enhances thermal performance while maintaining equivalent mechanical properties of honeycomb cores. Visit our products here