Source: Sika China

As global wind power installations surpass one terawatt, the speed and quality of turbine and blade repairs will be crucial to the production of clean energy. User-friendly repair systems, rapid curing blade repair technologies, and evolving automated maintenance techniques are all essential components of turbine blade repair solutions. As a long-standing partner of global wind turbine blade manufacturers and field service teams, Sika provides customized wind turbine blade repair solutions for manufacturers, injecting robust momentum into the thriving wind power industry.

Towards the Next Terawatt

2023 marks a significant milestone for the wind energy sector. After four decades of continuous growth, cumulative wind power installed capacity has reached one terawatt, sufficient to provide clean energy for one million households for a year. The next terawatt milestone for cumulative wind power installed capacity is expected to be achieved within the next seven years. With the targets set by the Paris Agreement and COP26 looming, and up to 75% of existing wind turbine installed capacity soon to be out of warranty, the need to extend the service life of wind turbines and minimize their downtime has become more urgent than ever.

Speed: A Critical Demand for Industry Development

In today’s industry environment, Original Equipment Manufacturers (OEMs), Internet Service Providers (ISPs), and asset owners face extremely challenging tasks. They need to organize hundreds of thousands of maintenance technicians to travel to many challenging locations on Earth to inspect and maintain complex wind power equipment. Many factors are intertwined in this process, with speed being the most critical one. This includes the speed of training technicians, executing maintenance tasks, and operating supply chains; of course, there is also the speed of innovation that drives everything to proceed smoothly, optimizing processes and improving efficiency. Speed has become a core factor determining their success.

Rapid Curing Blade Repair Systems

In addressing blade defect issues, Sika’s manual lamination solutions demonstrate significant advantages. Among them, SikaBiresin® CR910, as a rapid-curing resin, significantly shortens the cycle time required for various in-factory rework and field repair tasks.

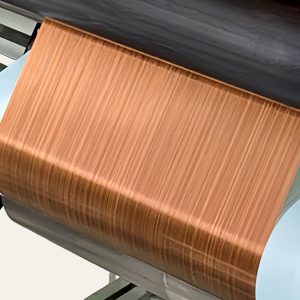

Optimized Blade Balancing In the wind power industry, blade balancing is a labor-intensive task. Excessive downtime due to repairs can lead to significant losses in energy production. For blade models that include balancing chambers, this critical process should be relatively simplified. However, it is often wasteful and time-consuming, involving manual mixing of balancing materials and imprecise tube injection operations. SikaForce® -710 L30 makes this process unprecedentedly simple. As this two-component adhesive has a 4:1 mixing ratio, the mixing process is quick and precise. Once mixed, the resulting high-density liquid balancing material has an ideal viscosity, enabling rapid, clean, and accurate injection. The final result not only makes the repair workers’ work easier and more efficient but also utilizes the material more effectively.

Next-Generation Automated Wind Turbine Blade Repair Technology

In the current trajectory of industry development, despite the continuous emergence of new materials and application technologies, the global shortage of repair technicians poses one of the greatest challenges facing the industry. To address this, Sika has forged close collaborations with technology companies to jointly develop robotic repair processes, integrating various adhesives and composites for groundbreaking applications. These innovative initiatives serve as a valuable supplement to professional technicians, ensuring that repairs can be completed more swiftly during periods of staffing shortages, thereby reducing downtime. Additionally, they significantly enhance the safety of personnel, mitigating the risks associated with inspections, maintenance, and repairs conducted under arduous conditions.